DIY 3d Printer

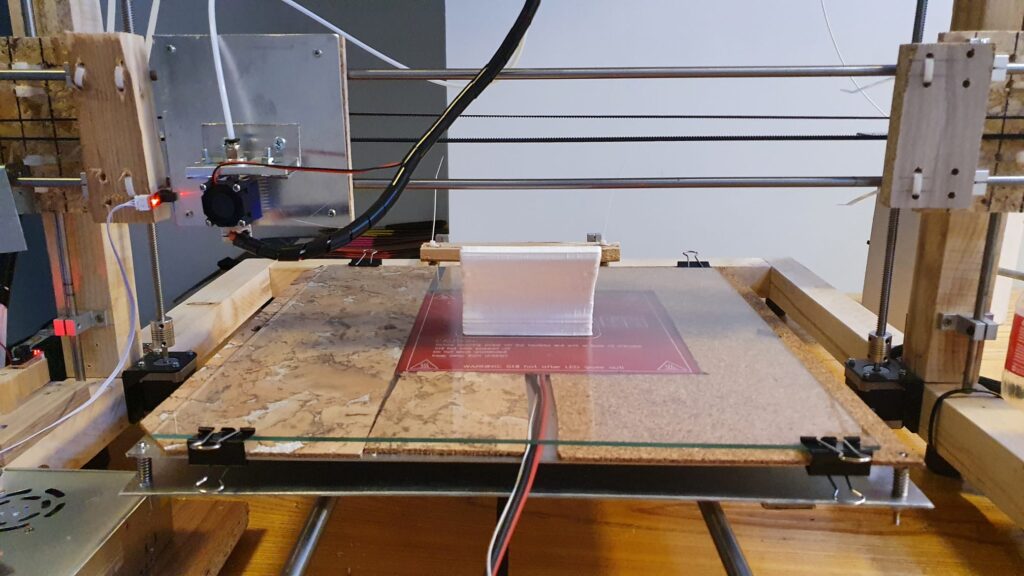

When I started exploring more in FDM 3d printing i decided to make one on my own 3d printer at least possible price in quest to explore the technology more deeper.

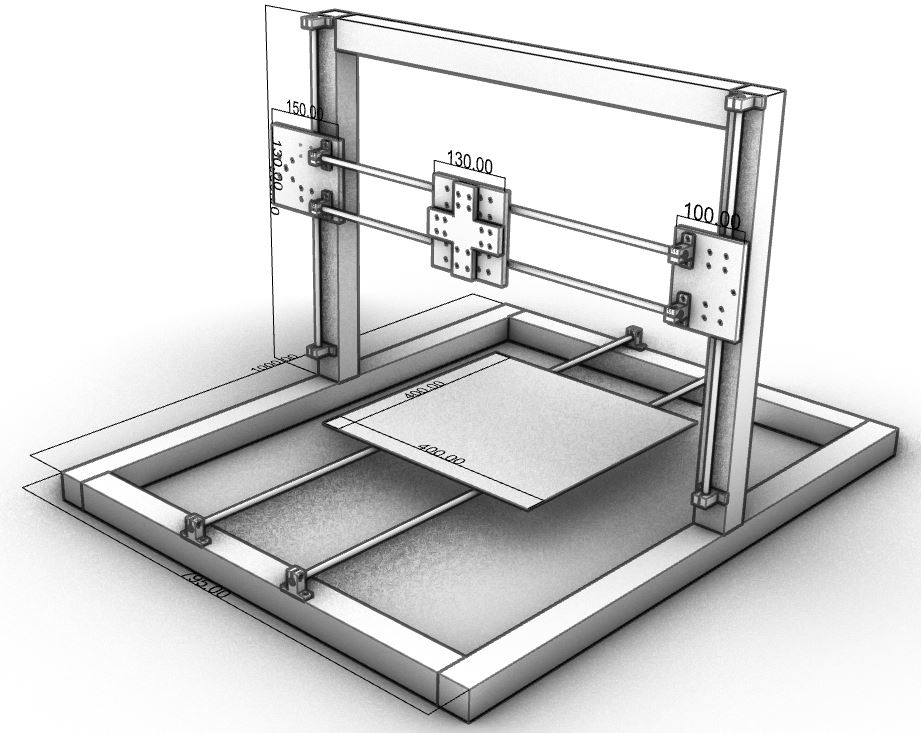

The printer design i’ve worked on has a print volume of 400mm X 400mm X 400mm and is a cartesian 3d printer.

Hardware-

- RAMSPS 1.4

- 12 mm steel rods

- 8 mm steel rods

- SC8UU linear motion bearing

- SC12UU linear motion bearing

- SK8UU Linear motion Rail Shaft Rod

- KP08 pedestal bearing

- T8 8mm Lead screw with nut

- Stepper motor coupler 5mm to 8mm

- GT20 tooth flanged pulley

- GT20 timing belt 4mtr.

- NEMA 17 mounting bracket – 4 nos.

- NEMA 17 stepper motor – 4 nos.

- a4988 stepper motor driver

- optical end switch

- Power supply 12V/20A

- MK8 extruder 175mm

- 1.75mm filament for 3d printing

- PCB Heatbed MK2b

- Arduino Mega 2560

- 3d printer hotend -0.4mm nozzle

- Heatbed thermistor

To keep the cost at minimal i used wooden frame which is made using 45X45 mm wood.

After frame completion, X, Y & Z axis stepper motors were fixed in place. Z axis has been provided 2 Nema 17 stepper motors. X & Y axia have 1 motor per axis.

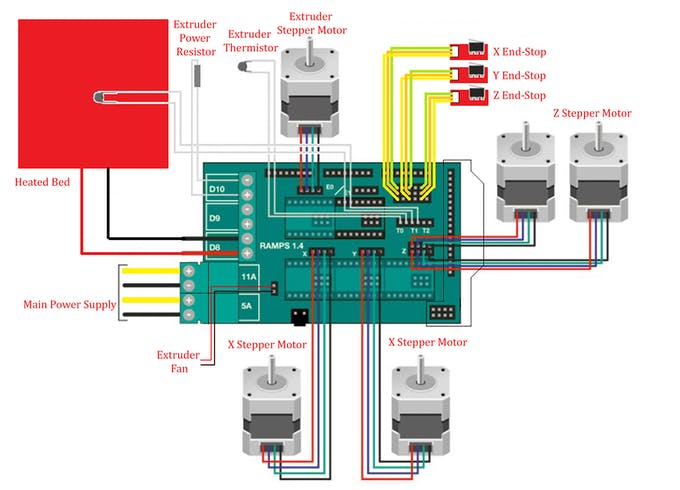

The electronics are installed as per the below schematics:

Second upgrade – First iteration of this printer used Ramps 1.4 board with A4988 motor drivers which end up giving a lot of noise during printing due to its resolution of micro steps being upto 1/16. To reduce noice, vibrations and resolution the printer was upgraded with a new motherboard SKR1.4 with TMC2208 driver. These drivers are super silent.

Software-

Marlin firmware is been used as a OS for 3d printing and was uploaded using Arduino IDE

Source –

https://www.arduino.cc/en/Main/Software

Initially i used Slic3r which is a open source slicing and pronterface to control the printer using serial port.

After a while i have switched to Cura slicer as it provides wide variety of settings.

After some of the failed prints and tweaking some marlin settings, it was a success and had really nice print.

Problems overcomed –

- The printer was very loud as the stepper drivers used are a4988 which will are now upgraded with silent stepper drivers TMC 2208

- Printer had a potential to be upgraded to 32 bit board rather than arduino. And is now upgraded with SKR 1.4 turbo which has really reasonable price and excellent performance.

Future plans:

- I would like to upgrade this printer to a clay 3d printer.